Current Projects

Current Project > Civil/Infrastructure

Recycled Concrete Safety Barriers – SafeRoads & University of Melbourne

25 April 2023

Australian ingenuity delivers next generation of road barriers to increase public safety and decrease waste.

A new generation of safety barriers made from tyre-derived materials – offering enhanced safety benefits, a longer life span and cost-effective solutions for a variety of industries.

T-Lok Rubber Safety Barriers have been developed by Saferoads and researchers from the University of Melbourne’s Advanced Protective Technologies of Engineering Structures (APTES) Research Group, with funding and support from Tyre Stewardship Australia (TSA).

The crash test at Victoria’s Lardner Park facility in September demonstrated that rubberised concrete road barriers will decrease impact severity and are a viable use of end-of-life tyres that would otherwise go to waste.

Saferoads CEO, Darren Hotchkin, said: “This new product will enable Australia to recover 115 tonnes of used tyres for every 10 kilometres of the Rubber T-Lok road safety barrier produced.”

University of Melbourne Professor Tuan Ngo, who leads the Advanced Protective Technologies of Engineering Structures (APTES) Research Group said: “This full-scale test is a tangible success for our project to invent sustainable uses for waste tyres.

“Road users are the winners here. The test showed that designed rubberised concrete road barriers will help reduce the force of impact thereby reducing the likelihood of injury and death, as well as being less damaging to the barrier itself. Debris emanating from shattered concrete road barriers, which may create another safety hazard after a crash takes place, is substantially reduced.

“We are very passionate about our work in this area and very keen to share outcomes that can save lives, increase road safety, and use recycled materials in a cost-effective manner.”

With enhanced safety benefits and a longer lifespan, it offers a cost-effective solution for a variety of industry sectors that make and use safety barriers, such as: manufacturing, engineering, construction, mining, outdoor event management and government road safety programs, especially in regional, rural and remote areas.

“This is yet another example of Australian ingenuity and innovation at its best, and we’re very proud to have supported a new home-grown product go from the lab to the real world,” says TSA CEO Lina Goodman.

The Innovators

- Saferoads

- University of Melbourne’s Advanced Protective Technologies of Engineering Structures (APTES)

- TSA Market Development team

The end result

A world first for Australia.

An innovative use of Tyre Derived Material (TDM) that will enhance public safety and support the recovery of end-of-life tyres in Australia – 1 kilometre of T-Lok barriers uses 12 tonnes of recycled rubber which is the equivalent of 2,000 passenger tyres, and it is projected the product could use up to 60,000 (360 tonnes) passenger tyres per year.

The inclusion of rubber crumb derived from tyres enhances the flexibility and durability of the concrete barrier resulting in better energy absorption, reduced risk to vehicle occupants and increased barrier lifespan.

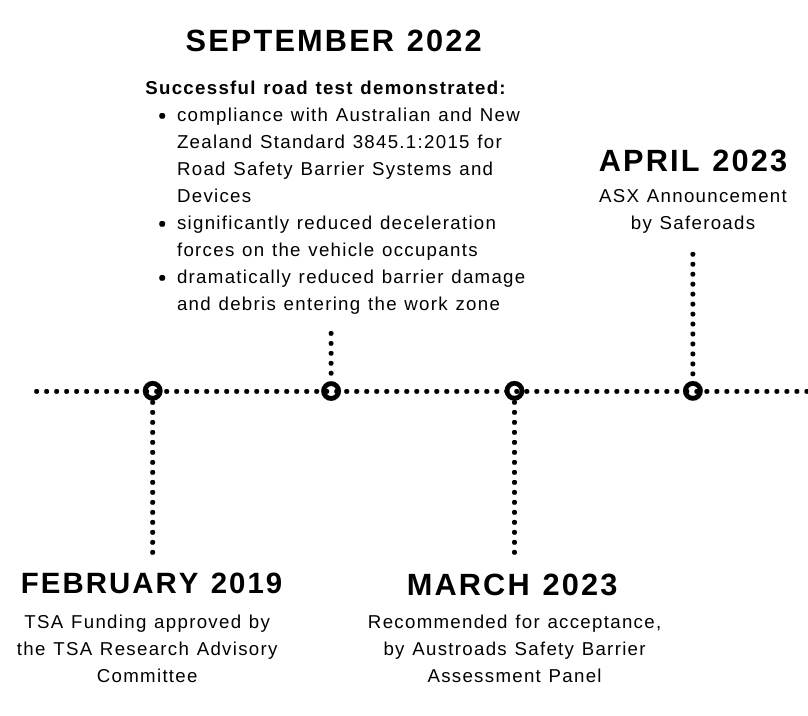

Timeline

TSA Fund Investment

$180,000 and team support for product design, testing, building and commercialisation.

Contribution to Australia’s Circular Tyre Economy

- Tyre Derived Material (TDM) Product Design

- TDM Product Manufacturing

- TDM End Market Development

Markets that will benefit from this

- Australian Public

- Construction

- Engineering

- Government / Civic Works

- Manufacturing

- Mining

- Outdoor Event Management

- Waste Recyclers and Processors

Related