Latest News

TSA News > Media Release: Final Call to action for industry to fix the problem

Media Release: Final Call to action for industry to fix the problem

27 November 2023

Final call to action for industry to fix the problem: Minister’s priority list makes it clear that tyres, conveyor belts and tracks, are a priority waste stream that can no longer be ignored

Australia’s Environment Ministers have doubled down on what they expect from industry to fix the national tyre waste stream problem, as part of critical next steps to transition the nation to a circular economy.

At their November 2023 meeting in Adelaide, they agreed to:

- retain the priority listing for passenger, bus and truck (automotive) tyres;

- expand the listing to include Off-The-Road (OTR) tyres and related products such as conveyor belts and rubber tracks; and

- pursue a framework that will accelerate product stewardship by better coordinating work across governments, with Western Australia leading on tyres.

Tyre and related rubber product manufacturers, importers, distributors, and retailers have been given a clear deadline of November 2024 to undertake improved and measurable product stewardship action.

In particular, tyre importers not currently contributing to Australia’s Tyre Product Stewardship Scheme (the voluntary Scheme) have been put on notice that, if they want to avoid government regulation, they should commence formal participation.

TSA CEO, Lina Goodman welcomed the Priority List updates: “These decisions show Australia’s Environment Ministers have a strong understanding of the complexity of end-of-life tyres, the current risks they pose to our natural environment and human health but also the opportunity we have here for the Australian economy.

“Including OTR tyres, conveyor belts and rubber tracks, which have the potential to generate $70 million of rubber and steel per annum, puts us firmly on the path to an ‘all-in’, inclusive scheme which is fairer for everyone, from metro to regional, rural, and remote areas.

“If we leave one sector out, whether it’s automotive or OTR, we will never be able to recover the materials needed to stimulate manufacturing, commerce, jobs, and innovation.

“Now is the time to act. The longer we take to convert these risks into the opportunity they offer us, the bigger the risks will grow and the harder it will be to manage them.”

No more time to waste, as burden on local councils and communities grows

Recent data shows us the reality for the environment and communities if we continue to delay decisive action on the recovery of end-of-life tyres and related rubber products:

- Recovery of used car, bus, and truck (automotive) tyres has gone backwards, having dropped to under 80%, a sharp downward trend since the 2019-2020 peak of 90%.

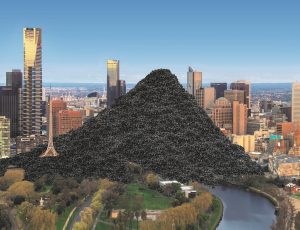

- The equivalent of 11.3 million car tyres are being stockpiled, illegally dumped, landfilled, or hidden in warehouses, on industrial sites, unsuspecting landowners’ properties, and even national parks increasing the risk of mosquito-borne diseases, toxic fires, and contamination of our built and natural environment.

- Australia still exports 70% or more of its recovered end-of-life tyre derived material overseas, often to developing countries. This means we are effectively exporting opportunities for local manufacturing and job creation.

- Currently, only around 10% of used OTR tyres and only very small tonnages of conveyor belts and tracks from mining, agriculture and construction are recovered, compared to global leaders such as Canada which recovers 87% and France 78%.

- Only 57% of tyre importers and 7% of auto brands (by volume of tyres/vehicles) are currently contributing to the voluntary Scheme, which means the majority are unfairly free-riding on the back of those who are taking responsibility for their products

Goodman underscores the urgency Australia now faces: “Whilst we applaud the tyre and auto industry pioneers who contribute to the voluntary Scheme, it’s clear that voluntary arrangements have reached the peak of what they can achieve, and we are nowhere near where we need to be.

“Unless the Scheme is regulated, it will become a race against time to shift the numbers in the right direction for Australia; and every year that goes by takes us further away from reaching a point we can benefit from being custodians of our own waste.

“And whilst we delay, it’s those who can least afford it – local councils and communities – that are footing the bill, particularly in regional, rural, and remote areas. They pay the price for management of waste and its associated health risks such as mosquito-borne diseases, toxic fires, and contamination of our built and natural environment.

“These are the same communities that bear the brunt of environmental forces – such as drought and fire – and can ill-afford resources being diverted from local services.”

No more excuses: there is a clear pathway forward

Australia has the product stewardship foundations in place to enable manufacturers, importers, distributors, and retailers to take action now, such as:

- expanding and improving the industry-led solutions

- diminishing free riders

- improving product design and supply chain capabilities to increase durability, reparability, re-usability and/or recyclability

- measurably supporting good product stewardship and circular economy progress.

We know a circular tyre economy works. Thanks to the 17 tyre importers and three auto brands that do contribute to the voluntary Scheme, TSA has been able to invest over $9.2 million into developing markets for tyre-derived materials (including roads, permeable pavement, playgrounds, and road safety barriers) that clearly show the value a circular tyre economy can deliver for communities all around Australia.

The technologies to recover and recycle end-of-life tyres, including OTR rubber products, exist and are being used here and around the world.

The collaboration that is needed between governments at all levels, industry, tyre manufacturers, recyclers, logistics operators and local communities is already happening and continues to be fostered by TSA. This includes support for co-designing a product stewardship scheme that is fit for purpose with greater scope and capability, and fair for all.

The evidence base to guide decision making has been built, clearly pointing the way forward, including:

- in-practice exemplars from all over the world

- significant research undertaken here in Australia that identifies everything we need to do to make a circular tyre economy work, such as a regulated scheme

- a study, another initiative by the EMM, in Western Australia which provides a foundation for guiding principles and a framework that can be used across jurisdictions

- identification of 11 catchment areas in regional, rural, and remote areas where we can concentrate our efforts to have the biggest impact, create reliable economic opportunities for investors and local communities, and shore-up future successes across Australia.

“What more do we need? And if not now, then when?” says Goodman.

“There is no doubt, times are tough for industry, businesses, and communities right now; but strengthening our nation’s circular tyre economy could be one pathway through the current socio-economic challenges.

“Our options for recovering these valuable resources are not going to get any clearer or easier.

“It’s time to accept the evidence, think about the future we want, and act on the choices we can, and should, make today.”

More on the data behind this release

- Minister’s Priority List 2023-24

- Environment Ministers’ Meeting – 10 November 2023 – Agreed Communique

- Sustainable Communities and Waste – National Environmental Science Program – Exploring opportunities for increasing value recovery from end-of-life tyres and conveyor belts in Western Australia

- TSA Tyre Recovery Data for 2022-23

- TSA Tipping the Balance Report 2023

Media contact for TSA:

Sandra Scalise, Tyre Stewardship Australia, Director of Strategic Marketing Communications

Email: sandra.scalise@tyrestewardship.org.au

Phone: 0491 272 721

Tolga Huseyin, Tyre Stewardship Australia, Marketing Manager

Email: tolga.huseyin@tyrestewardship.org.au

Phone: 0409 270 038

Background on Tyre Stewardship Australia

Australia’s tyre product steward was established in 2014 to implement the national voluntary Tyre Product Stewardship Scheme (TPSS) – an ACCC-authorised industry framework to reduce the environmental, health and safety impacts of the 56 million Equivalent Passenger Units (EPUs) which reach their end of life in Australia each year.

TSA’s vision is of a circular economy for end-of-life (EOL) tyres that contribute to a sustainable society.

It works all along the tyre supply chain to minimise waste and increase value for government, industry, businesses, and consumers, by:

- Accrediting and monitoring compliance of TPSS participants – now 1,700 and counting, including tyre manufacturers, retailers, collectors, and recyclers who are committed to sustainable practices.

- Working with levy contributors to invest in market development initiatives – over $9 million invested to date, including:

• research and development

• commercialisation of new productive uses for EOL tyres driving the transformation of a waste product into a useful commodity, creating new industries and jobs while reducing the environmental harm caused by the illegal dumping of old tyres. - Providing a range of ESG tools and services for use by government, industry, R&D and consumers, including

• Foreign End Market Verification (FEMV) platform – the only global platform that verifies Australian-generated end-of-life-tyres are not causing environmental or social harm at their final destination.

• Sustainable Outcomes Indicator star rating which drives and promotes best practice operations and the development and use of tyre-derived materials and products in the Australian market.

• Circular Collaborator platform which supports products manufactured in Australia using Australian-made tyre-derived material.