Latest News

TSA News > Taking the wheel

Taking the wheel

1 August 2023

Lina Goodman, CEO, Tyre Stewardship Australia, is drawing inspiration from global schemes to bring Australia’s circular tyre economy across the line.

The tyre industry has said loud and clear that Tyre Stewardship Australia (TSA) is doing the best it can, but it’s not enough. More needs to be done.

At the helm of Australia’s product stewardship scheme for the past four years, TSA Chief Executive Officer Lina Goodman absolutely agrees more needs to be done, but she questions how much more can be achieved under the current construct.

“Government has wanted industry to do this on their own and take responsibility for the product that they’re distributing to the sector,” Lina says. “And I think that just hasn’t been able to be achieved. We’ve tried and we’ve come a long way. But it hasn’t worked.”

TSA was established as a voluntary product stewardship scheme to create productive outcomes for end-of-life tyres. In almost a decade it has accredited 1700 participants and committed $9 million to projects to advance the use of tyre-derived material.

What it hasn’t been able to achieve is stamp out free riders, with only a five per cent increase in participation by passenger and truck tyre manufacturers since the scheme began.

In July 2022, after deep consultation across the tyre industry, an independent review, mandated by the Australian Competition and Consumer Commission (ACCC), indicated the scheme had run out of bite. End-of-life tyres were added to the Minister’s Product Stewardship Priority List in October 2022. At the time, Tanya Plibersek, Minister for the Department of Climate Change, Energy, the Environment and Water, said the priority list made it clear, if industry doesn’t act, government will.

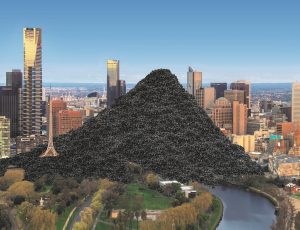

The government doubled down at the June Environment Minister’s meeting, agreeing to fast-track a review of a tyre stewardship framework. Lina says it’s a strong signal to the market that it’s time to get serious about circular economy for used tyres in Australia. “A regulatory process means that we do away with the environmental disaster that we’ve seen here in Australia over the past years whether it’s stockpiling, illegal dumping or fires,” Lina says. “All these things, we hope, will be mitigated because tyres will not have the chance to fall into the hands of rogue operators, but have a proper pathway that they must go through.”

The Minister’s priority list requires three actions by October 2023 – increase the consumption of tyre-derived material in Australia; all retailers need to be participating in the scheme; and all tyre importers bringing tyres into Australia need to be part of the scheme. Lina says that just several months away from the deadline, none of the requirements have been met. “Government responded quickly to this lack of action by the industry,” she says. “The government is now asking, ‘does there need to be a regulatory response to make these actions happen? And what does that look like?”

Lina says a circular economy cannot succeed in a vacuum, it must be supported by regulation and be in line with other operators in the global economy.

TYREWISE – NEW ZEALAND

It’s been a lengthy journey for New Zealand’s tyre stewardship scheme, Tyrewise, from the first phase of the project in 2012 to a declaration of priority product status for tyres in 2020.

The scheme is being implemented in 2022-23 and, unlike TSA, never operated as a voluntary scheme. Adele Rose, Chief Executive Officer of 3R Group, implementation project managers for Tyrewise, says the country’s tyre industry was clear from the start that it wanted a mandatory framework so that there was a level playing field and no free riders.

3R worked closely with the industry to keep the Tyrewise Working Group together after tyres were not declared as a priority product in 2015. Adele says

the change of government in 2017-20 renewed hopes of regulation when tyres were declared a priority product in 2020. Adele says communicating with industry to maintain relationships and “hold the line” is important.

“You need an organisation that’s willing to lead,” she says. “3R Group, as project managers of Phase One, was willing to do that despite there being no

funding. We believed regulation was the right thing for Aotearoa New Zealand and we were willing to hold those relationships over the years.

“The industry was always clear in its view that Tyrewise would not progress as a voluntary scheme. That meant that maintaining critical contacts within government during the design years was equally important to ensure that the scheme did not end up in the too hard basket.”

There’s been a few lessons learned along the way. During the scheme’s design phase several methods of declaration of tyre volumes were explored. The main differences were declaration direct to the product stewardship organisation or declaration via first point of import or registration. For import, this would be via NZ Customs on loose tyres or non-road registered vehicles, and for registration via NZ Transport Agency for vehicles upon initial registration for on-road use.

Adele says the method of brand owner first importer via the first point of import was initially preferred by the industry. The view was that this would be administratively efficient and there would be less risk of any leakage of market sector information.

She says with hindsight, brand owner first importer declarations to the product stewardship organisation would have been preferable. However, New Zealand’s current Waste Minimisation Act 2008 is not designed for this type of declaration at first point of entry to market and has

required some workarounds.

“This means additional agencies beyond the Ministry for the Environment, which is responsible for the Act, have had to be involved, including Treasury as the advanced stewardship fee is treated as public funds, the same way as a tax,” Adele says. “The reality is that having government collect fees and data, and then find a mechanism to provide those funds and data to a scheme is administratively heavy.

“Data is unable to be passed to a nongovernment entity, therefore significantly restricting the useful flow of data to the managing entity. This would have allowed further checks and balances.” Adele says that over the journey, success for all involved was to achieve a level playing field that removed the risk of free riders. That hasn’t changed, but an unexpected benefit has been the way that the collection, transport, and processing sectors have matured since the declaration of tyres as a priority product in 2020.

Despite a clear direction, there continues to be challenges, including changing governments. New Zealand’s three-year term is too short, Adele says, to achieve much and there is a lack of public consensus on environmental action.

Government processes also take time, especially when implementing regulated product stewardship for the first time – Tyrewise is the first of six product categories declared priority product and will be the first “cab off the rank”. “This part of the regulatory toolkit hasn’t been used before and that of course throws up challenges,” Adele says.

Adele offers some advice to Australia and TSA on its journey: Keep up the communication and involve all of the key stakeholders at the highest level right from the start; leverage the strengths of what has already been achieved, such as end market verification; design the scheme around brand owner first importer declarations to the product stewardship organisation, rather than to government; and watch out for the variabilities in tariff code versus actual tyre size when setting up the payments system.

TIRE STEWARDSHIP BC – BRITISH COLUMBIA

Rosemary Sutton, Executive Director of Tire Stewardship BC, agrees communication is key to any successful tyre stewardship scheme. “Consult, consult and consult, and if you think you’re done, consult again,” Rosemary says.

“Everybody’s vision and objectives in the end are the same. If you can layer in collaboration, co-operation, and harmonisation, it’s going to make all the difference.”

Tire Stewardship BC is in the enviable position that its program has matured and reached what Rosemary describes as a steady state. For several years demand for tyre-derived material has exceeded supply.

“It’s an incredible situation to be in,” Rosemary says. “We lucked out with the recycler in our province. They saw the scheme as their business and that they needed to be the ones investing equipment and finding end markets.” Tire Stewardship BC began as a government-run program in 1991 in response to a fire at a tyre recycling facility near Hagersville, Ontario. The fire of 14 million tyres burned for 17 days.

Rosemary says the British Columbia Government wanted to avoid a similar environmental disaster and implemented a fee that the consumer paid when purchasing tyres. The fee went to the government, which in turn was used to fund tyre recycling.

In 1994, the tyre industry pushed for the scheme to be under government regulation but for tyre producers to manage it. At the time the ministry was looking at other product stewardship, such as beverage containers, so the framework already existed.

In 2006, tyres were added to regulation, extending the scope of the program. That was the catalyst for change, Rosemary says. “Once the scheme reached a steady

state, we saw the recyclers start to invest,” Rosemary says. “They realised they had something concrete. They had stability and they really started to invest in their businesses.

“You need to ensure recyclers are compensated for what they do.” She says the scheme now has evolved into a continuous mode of improvement, with more focus and research into finding new markets for recycled rubber.

In the early days, success was measured by the number of tyres collected and recycled. Rosemary says success now is seeing the progression, innovation, and investment in the industry. “Regulation gave us the ability to know that this program was a level playing field,” she says. “What we have seen is a huge shift in industry, especially at tyre manufacture level, going from being a little bit more outside looking in and not wanting to dip their big toe in, to a complete 180 and they’re the ones pushing and looking for alternatives and trying to hit environmental targets. “Some of that is external forces, the world is changing, but it’s so nice to see them at the table, taking responsibility and them wanting to come up with solutions.”

ALIAPUR – FRANCE

The aim of the French extended producer responsibility scheme, Aliapur, was always to ensure that every tyre in France was collected and recycled at end-of-life.

Created by tyre manufacturers Bridgestone, Continental, Goodyear, Michelin, and Pirelli in 2003, the scheme is financed by an eco-tax, paid by tyre manufacturers or importers. In 2021, Aliapur processed 388,109 tonnes of end-of-life tyres, or the equivalent of 48.2 million passenger vehicle tyres, representing 80 per cent of the total volume to be processed annually in France.

Hervé Domas, Aliapur Managing Director, says the scheme was regulated from its beginning, so there was always the political will to do things properly. Something, he says, Australia’s government should take note of. “They have to implement such regulation if they seriously want all the tyres to be collected,” he says.“If producers do not have to pay a fee, nothing will be done seriously. You need some money to collect, to shred the tyres, and you need some money to deliver the shred to end markets – if you don’t receive subsidies and it’s not mandatory you have no possibility to work in good conditions.

“I have a feeling TSA is just waiting for this regulation to have better results for end-of-life tyres.” Hervé says Australia is close to the perfect situation. TSA has done the leg work and has a ready set of proven industry applications for recycled rubber. He believes tyre manufacturers worldwide want tyre stewardship to be a success.

“Tyre manufacturers absolutely don’t want that their product finishing its life in nature,” he says. Lina agrees Australia is in a great position. She says the success, and failures, of international schemes allows Australia to cherry pick what will work best for the nation.

“The world is getting smaller and the great thing about these international organisations is that we’re not competing against each other,” Lina says. “We’re all working for the same thing. It’s wonderful because we can work together. “Australia’s got everything to gain and nothing to lose.”

Original article posted here